Heat Pressure Welder

Applicable to a wide variety of materials

The heat pressure welders have been designed primarily for use with high carbon steel wire rods that are normally difficult to join, and copper wires that are required to have high connection performance to cope with high speed wire drawing machines.

They can however be applied to many other materials.

Characteristics

With the heat pressure welding process, which is a two-step upsetting type, undesirable defects within the metal structure are eliminated when the excess molten material is forced out from between the joining surfaces. This feature assures unprecedented weld performance. In the case of high carbon steel wire rods, decarburization,which is common in the conventional process,does not take place. Furthermore,there is no decrease in hardness. In the case of copper wire rods for electric application, the welded section is not subject to formation of over heat zone, oxygen absorption or decrement in strength,unlike in the conventional process. These features are particularly useful in the welding of oxygen-free copper stock which must be protected against oxygen absorption of flat pieces that are subject to severe working conditions.

【Ferrous】

- P.C.steel wire rod, spring steel wire rod and other High carbon steel wire rods.

- Various types of stainless steel wire rods.

- Various types of welding rods.

- Low alloy steel wire rods.

- Steel wire strand.

- Steel tire cord.

【Non-Ferrous】

- Copper wire rods for electrical conduction.

- Oxygen-free copper wire rods for electrical conduction

- Aluminum wire rods for electrical conduction

- Flat wire rods for electrical conduction

- Brass wire rods.

- Welding of stranded wires.

- Welding of different types of metallic wire and rods.

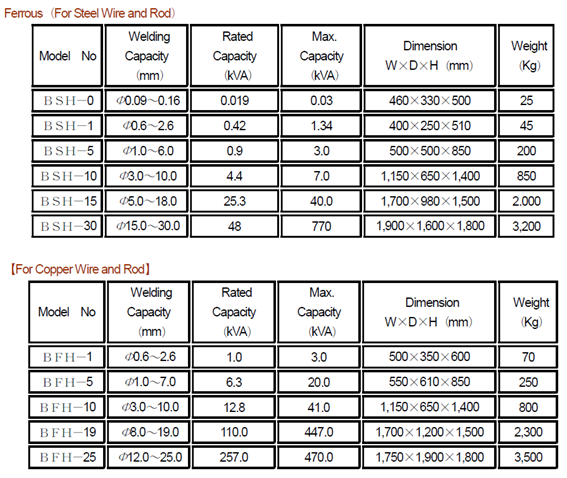

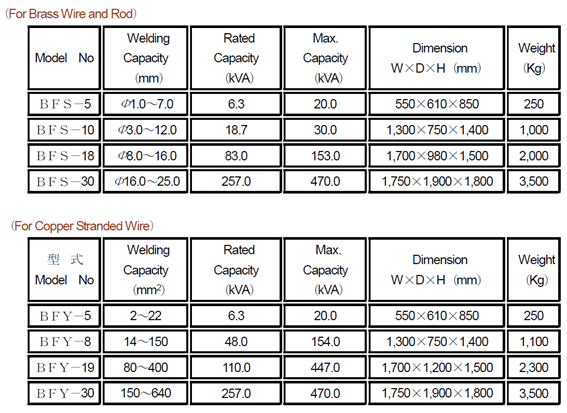

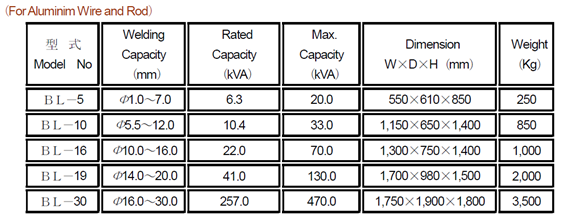

【SPECIFICATIONS】